Our State-of-the-Art Facility

Take a virtual tour of where the science of veterinary compounding comes to life

Welcome to NPLabs Veterinary

Our purpose-built compounding facility in Athens, Greece represents the culmination of over 19 years of experience in pharmaceutical compounding. Designed to meet and exceed international standards for pharmaceutical manufacturing, our facility enables us to create the highest quality compounded medications for veterinary patients throughout the European Union.

Every aspect of our facility has been carefully designed with quality, safety, and efficiency in mind. From specialized clean rooms for sterile compounding to dedicated laboratories for non-sterile preparations, our facility provides the optimal environment for creating customized medications that meet the unique needs of veterinary patients.

Virtual Facility Tour

Explore the different areas of our compounding facility and learn about the specialized equipment and processes that enable us to create customized medications for pets and animals of all species.

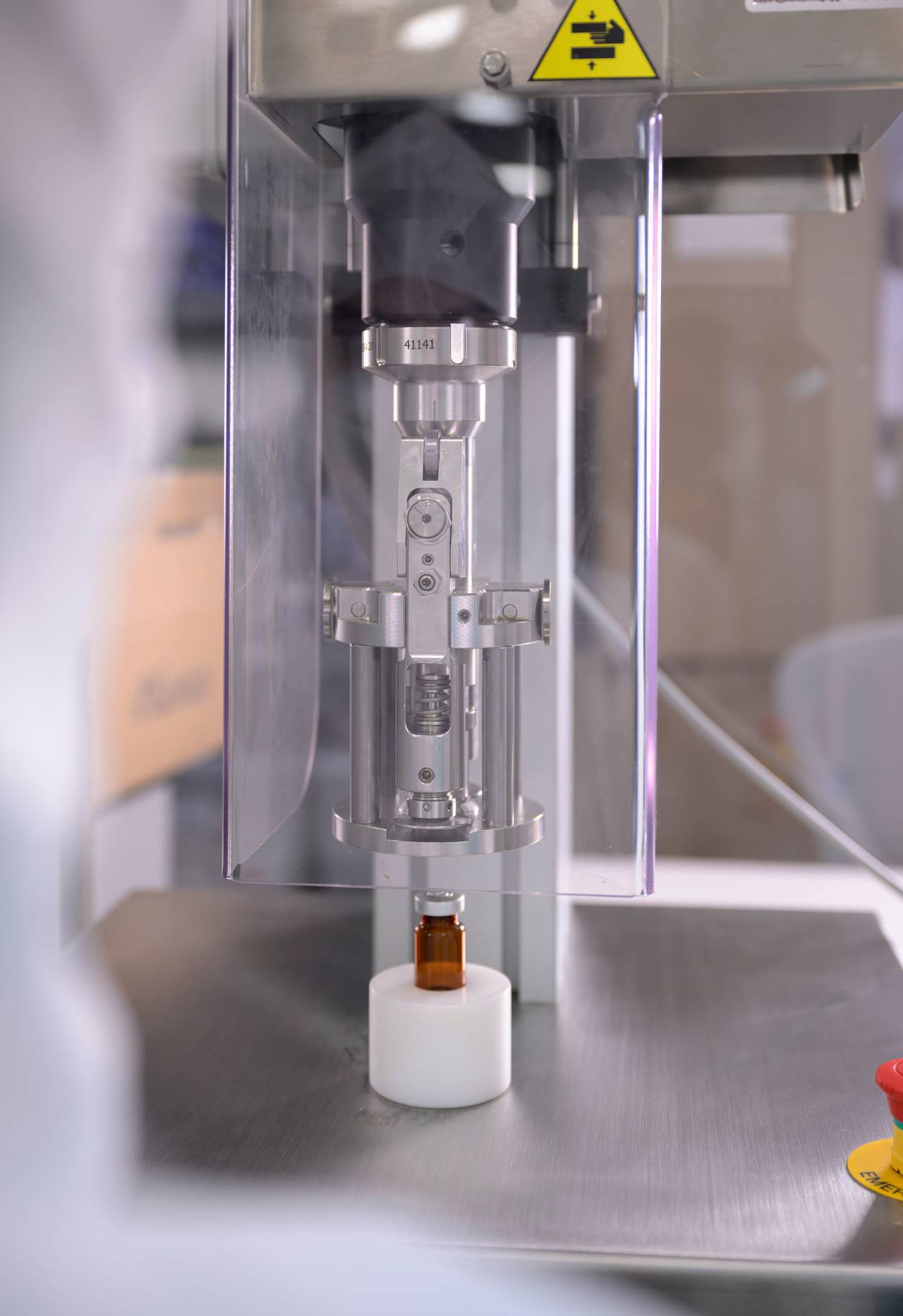

Sterile Compounding Area

Our sterile compounding area is designed to meet the highest standards for preparing injectable medications, ophthalmic solutions, and other sterile preparations. This controlled environment features:

- ISO Class 7 clean rooms with HEPA filtration

- Positive pressure differential to prevent contamination

- Laminar flow hoods for aseptic processing

- Continuous environmental monitoring

- Specialized equipment for sterile filtration and filling

Non-Sterile Compounding Laboratory

Our non-sterile compounding laboratory is where we prepare oral medications, topical preparations, and other non-sterile dosage forms. This laboratory features:

- Dedicated zones for different types of preparations

- Precision compounding equipment for accurate measurements

- Specialized mixing and homogenization equipment

- Flavor formulation station for palatability enhancement

- Advanced capsule filling and tablet pressing capabilities

Analytical Testing Laboratory

Our in-house analytical testing laboratory allows us to verify the quality, potency, and purity of both raw materials and finished preparations. This laboratory is equipped with:

- High-Performance Liquid Chromatography (HPLC) systems

- UV-Vis spectrophotometers for potency testing

- pH meters and osmometers for solution analysis

- Particle size analyzers for suspension quality

- Stability testing chambers for beyond-use dating verification

Research & Development Laboratory

Our R&D laboratory is where we develop and refine new formulations to meet the evolving needs of veterinary medicine. This innovative space includes:

- Formulation development workstations

- Pilot-scale manufacturing equipment

- Stability testing chambers for formulation validation

- Specialized equipment for novel dosage form development

- Collaborative workspace for pharmacist-veterinarian consultations

Facility Quality Control Measures

Our facility incorporates numerous quality control measures to ensure the safety, efficacy, and consistency of every compounded medication we prepare.

Environmental Monitoring

Our facility features comprehensive environmental monitoring systems that continuously track:

- Temperature and humidity in all compounding areas

- Differential pressure between controlled environments

- Particulate counts in clean rooms

- Air exchange rates in compounding areas

Cleaning & Sanitization

We maintain rigorous cleaning and sanitization protocols throughout our facility:

- Validated cleaning procedures for all compounding areas

- Regular surface sampling to verify cleanliness

- Specialized cleaning agents for different surfaces and areas

- Documented cleaning logs for all critical areas

Equipment Maintenance

All equipment used in our facility undergoes regular maintenance and validation:

- Scheduled preventive maintenance for all equipment

- Regular calibration of measuring instruments

- Performance verification before each use

- Documented equipment logs and certifications

Personnel Controls

Our staff follows strict protocols to maintain the integrity of our controlled environments:

- Comprehensive gowning procedures for clean room entry

- Regular aseptic technique validation for sterile compounding staff

- Controlled access to critical compounding areas

- Health monitoring for staff working in controlled environments

Facility Certifications & Compliance

Our facility maintains numerous certifications and complies with stringent regulatory requirements to ensure the highest standards of quality and safety.

EU GMP Compliance

Our facility complies with European Union Good Manufacturing Practice guidelines for pharmaceutical production.

ISO 9001:2015

Our quality management system is certified to ISO 9001:2015 standards for consistent quality processes.

USP <795> & <797>

Our compounding practices adhere to United States Pharmacopeia standards for non-sterile and sterile compounding.

Regular Inspections & Audits

Our facility undergoes regular inspections and audits to verify compliance with all applicable standards:

Internal Audits

- Monthly quality assurance reviews

- Quarterly facility and process audits

- Annual comprehensive system review

External Audits

- Greek regulatory authority inspections

- ISO certification audits

- Independent third-party assessments

Experience the NPLabs Difference

Our state-of-the-art facility enables us to create the highest quality compounded medications for your beloved pets.